Table of Contents

“Modular housing” tends to conjure images of shipping containers and temporary prefab boxes. That shorthand sells the concept short. The term refers to a diverse range of building methods that move construction off the job site and into the factory, not to cut corners, but to cut time, waste, and cost.

Across Europe and Asia, this shift is already well underway. In Sweden, more than 84 percent of detached homes are built using prefabricated elements. In Canada, modular remains marginal, not because the technology lacks merit, but because the regulatory and financial systems around it have failed to adapt.

At a time when Canada’s housing targets are growing more ambitious, modular construction offers one of the few credible paths forward. Understanding what it is, and why it matters, is essential.

Four Ways to Build Modular

There is no single modular model. What unites these methods is the relocation of labour from chaotic, weather-exposed job sites to controlled, efficient factory floors. The degree of completion, transportability, and site assembly varies.

Volumetric Modules

These are fully constructed, room-sized boxes, complete with drywall, wiring, plumbing, and windows, built off-site and trucked in for stacking and assembly. The benefit is speed; entire buildings can come together in weeks. The constraint lies in transport. Oversize modules often face logistical hurdles across provincial lines.

Panelized Systems

Here, structural elements like walls and floors arrive flat-packed and are assembled on location. Panelized builds are faster than traditional framing but more adaptable than volumetric ones. This method suits single-family homes, laneway infill, or anything requiring flexible delivery.

Hybrid Systems

A hybrid approach blends on-site framing with factory-built pods: often kitchens or bathrooms that slot into the structure like fitted components. These systems work best in mid-rise buildings where repetition is high, but full modular delivery may not be feasible.

Mass Timber and CLT

Cross-laminated timber (CLT) panels offer a sustainable, fast-install alternative to concrete or steel. Favoured in Europe and gaining traction in Canada, CLT enables quiet, clean builds in dense urban lots. It also performs well under modern energy codes, with strong carbon-storing credentials.

Why Modular Housing Matters Now

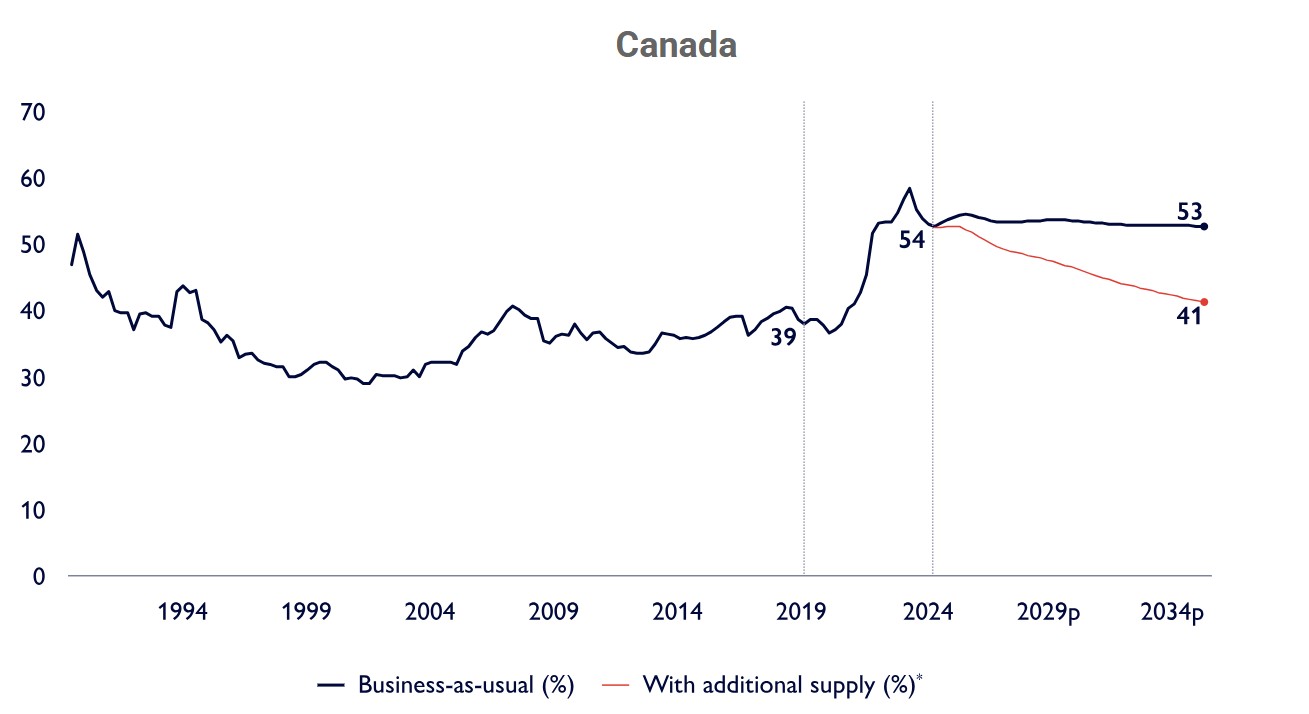

Canada’s construction sector is not building fast enough to meet demand. CMHC estimates the country must produce between 430,000 and 480,000 housing starts annually through 2030 to restore affordability. Last year’s output did not come close and future projections are equally sobering (see the chart below from the same report).

The Y-axis shows the ratio of average home price to gross household income (a measure of affordability). The chart projects two scenarios through 2035: one reflecting the status quo, and the other based on increased housing supply. Lower values signal improved affordability.

At the same time, one-fifth of the construction workforce is set to retire by 2032. Replacing that experience will take years and even the best apprenticeship programs cannot scale fast enough to fill the gap. Modular methods help mitigate this pressure by shifting repetitive, labour-intensive work into semi-automated settings. Fewer trades are required on site, and the work that remains moves faster with fewer disruptions.

Even when workers are available, delays start long before ground is broken. Canadian permitting timelines are among the slowest in the OECD. When approvals are issued, modular projects can often be delivered faster, sometimes in half the time, which protects budgets and improves the viability of lower-margin projects, including purpose-built rentals.

Not Every Modular Project Faces the Same Constraints

Each method interacts differently with the policy environment. Volumetric units need oversize transport permits. CLT panels often trigger separate building code reviews. Panelized systems may bypass some of those challenges, but often require finishing crews that modular factories could otherwise eliminate.

When policymakers design rules that treat these systems identically, at least one category suffers. Uniform regulations, while well-intended, can distort the economics of modular adoption. A permitting system that rewards speed for one method may inadvertently punish another.

Developers and builders aren’t asking for favours. What they need is clarity, especially across provincial lines, and financing tools that reflect how modular construction actually works. Most traditional funding structures tie draws to milestones achieved on site. Modular front-loads the work, which means capital must flow earlier. Without that alignment, timelines compress but funding remains stuck in place.

A System Built for Today

Modular techniques do not eliminate design or craftsmanship. They reorganize it. The sequencing changes, but the standards do not. If anything, factory-controlled conditions raise quality thresholds with fewer variables, fewer errors, and far less rework.

That shift also unlocks new roles within the construction workforce. Precision assembly, digital twin modelling, logistics coordination: these are not tasks one associates with traditional job sites, but they are already part of modular workflows in markets more advanced than ours.

The same project built by modular means will produce less waste, generate fewer noise complaints, and spend fewer months on city streets disrupting traffic or neighbours. Those are real economic, environmental, and social gains.

Want to know more about how modular construction fits into Canada’s housing future?

Chat with Valery, your AI-powered real estate assistant, for instant answers, insights, and project-specific guidance. Click her on the bottom right to get started.